No I am not ending this R2-A6 build blog, I am starting another one in addition to this one.

My man-cave/hobby room has gotten out of hand. It's turned into a dumping ground for unwanted tools and junk collected for future projects and unfinished ones. I am clearing it out completely, re-organizing and resetting my work space. I am finally going to college (it's been 13 years since I was in High school) and will need an office to take the on-line courses as part of my Bio-mechanical Engineering Technologies degree at Purdue. I also want to be able to pursue my hobbies like building this droid and other things.

With all this in mind, I decided to take this opportunity to totally re-do the room now dubbed my 'Ready Room.' This is pretty exciting as I've been waiting to get our next house to trek-i-fi a room for myself, but now with 4 years of college ahead of me before we can even look at moving I decided the time was nigh.

I am starting a new blog about it

here.I will be building R2 again soon. His naked legs and bare bones mock me every time I go in there and it's time to take things in hand. So hand me that hyper-spanner over there and lets get to work!

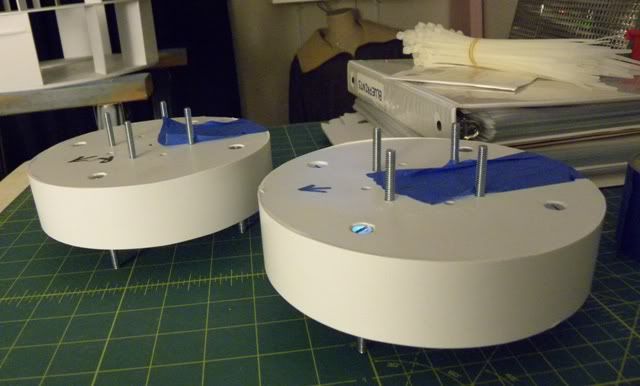

Oh, and the vacuum former is still in construction. got the major steel and wood body work done. A few more welds and I'll move onto the platten, oven, and vacuum systems. More to come on that.